Classification

Contact us

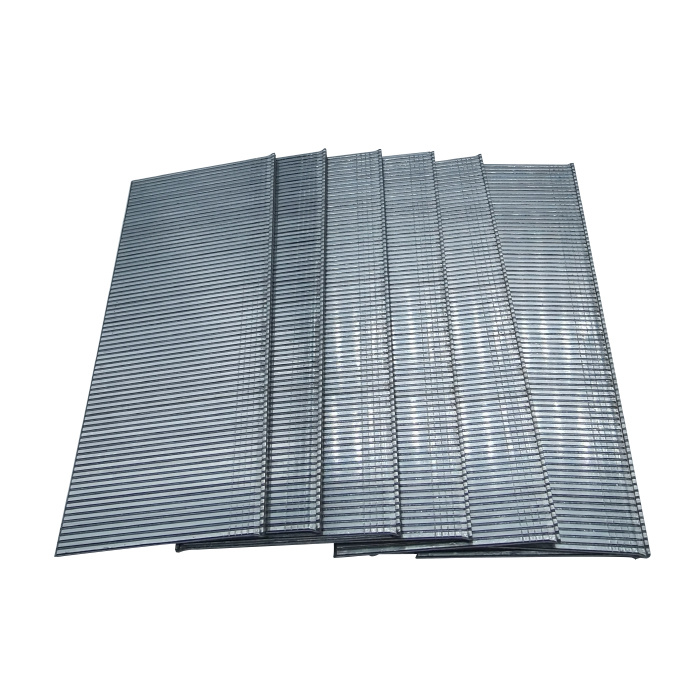

Straight nails are a type of row nails that are commonly used for construction with air nail guns, and are widely used in fields such as furniture, sofa, decoration, and other fields. There are many types of straight nails, mainly F type and T type. F and t represent the style of straight nails, while the numbers below represent the length of straight nails. Common specifications include F05, F10, F12, F13, F15, T32, T38, T40, T50, and so on. The main difference between f type straight nails and t type straight nails is the style of the nail head, and there are also certain differences in their nail retention force.

The wire clip is a nail used for fixing wires and cables, with a plastic sleeve and made of high-quality carbon steel. When purchasing, it is necessary to basically match the required fixed wires in order to have a good fixing effect. The galvanized wire clip has a diameter of 1.5mm-3.8mm and a length of 15mm-60mm.

The wire clip is a nail used for fixing wires and cables, with a plastic sleeve and made of high-quality carbon steel. When purchasing, it is necessary to basically match the required fixed wires in order to have a good fixing effect. The galvanized wire clip has a diameter of 1.5mm-3.8mm and a length of 15mm-60mm.

It is a screw without a head shape and is a deformation product of ordinary hexagon socket screws. It is mainly used for fastening the connection of hole positions in connection mechanisms with fixed countersunk heads, playing a role of locking, simple positioning, and limiting. One end of the headless screw is hexagonal, and the other end has specifications such as DIN916, DIN915, DIN914, DIN913, etc. It should be installed and used using a hexagon wrench of the same size. This screw can be screwed in as a whole, making it look flat and beautiful.

The tail of the drill tail screw is in the shape of a drill tail or a pointed tail, requiring no auxiliary processing. It can be directly drilled, tapped, and locked on the setting materials and foundation materials, greatly saving construction time. Compared to ordinary screws, they have a high tensile strength and maintenance force, and will not loosen for a long time after combination, making them safe to use. Specifications include: Φ five point five × 20mm - Φ five point five × 135mm Φ six point three × 25mm - Φ six point three × 300mm。

The tail of the drill tail screw is in the shape of a drill tail or a pointed tail, requiring no auxiliary processing. It can be directly drilled, tapped, and locked on the setting materials and foundation materials, greatly saving construction time. Compared to ordinary screws, they have a high tensile strength and maintenance force, and will not loosen for a long time after combination, making them safe to use. Specifications include: Φ five point five × 20mm - Φ five point five × 135mm Φ six point three × 25mm - Φ six point three × 300mm。